Cut & Sew vs. Seamless Leggings: What Are The Key Differences?

Cut & Sew vs. Seamless Leggings: What Are The Key Differences?

When it comes to activewear, leggings have become a wardrobe staple for both gym enthusiasts and casual wearers. However, not all leggings are created equal, especially when it comes to their construction. The two most common types of leggings are Cut & Sew and Seamless, and each offers unique benefits depending on your needs. In this blog, we’ll break down the key differences, advantages, and best use cases for each type of legging.

What Are Cut & Sew Leggings?

Cut & Sew leggings are constructed using traditional manufacturing methods. This involves:

Fabric Rolls: Fabrics are sourced in rolls and cut into individual pieces based on a 2D pattern.

Sewing Process: These pieces are stitched together to form the final garment.

Customization Options: Different fabrics and stitching techniques can be combined for unique designs.

Key Features of Cut & Sew Leggings:

Fabric Options: Offers flexibility to use various fabric types, including polyester, nylon, and blends.

Finishing Options: Allows for detailed finishing, such as top-stitching or cover-stitching.

Design Versatility: Can accommodate interlock knits, mesh inserts, or printed designs like camouflage or floral patterns.

What Are Seamless Leggings?

Seamless leggings are created using specialized tubular knitting machines, such as those from Santoni. The fabric is knitted in a circular motion to form a tube, reducing the need for excessive stitching.

Key Features of Seamless Leggings:

Minimal Seams: The tubular construction means fewer seams, enhancing comfort and reducing chafing.

Integrated Patterns: Allows for compression zones, texture variations, and branding directly knitted into the fabric.

High Stretch: Due to the nature of the knitting, seamless leggings offer exceptional stretch and fit.

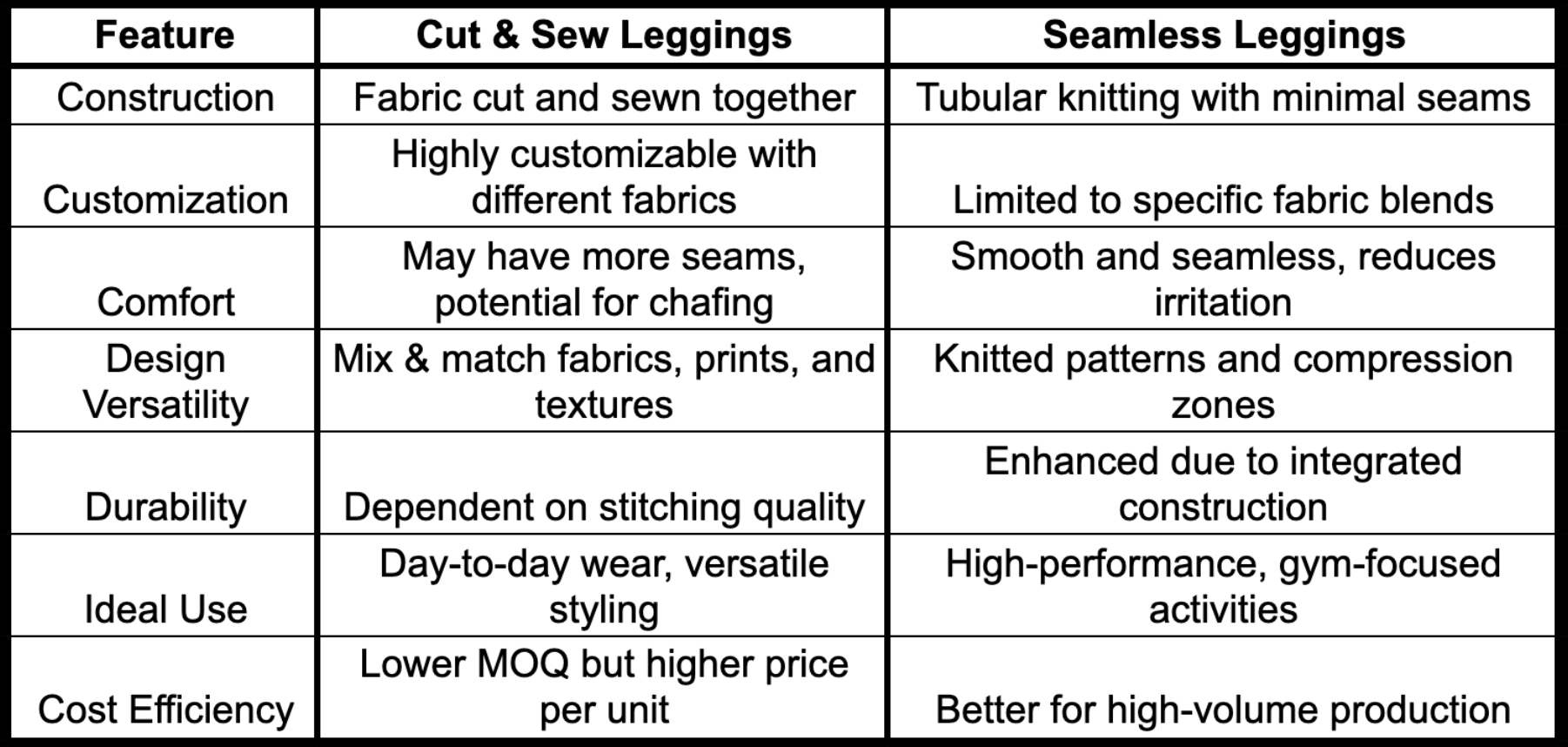

Comparing Cut & Sew vs. Seamless Leggings

Fabric Considerations

Cut & Sew:

Often uses polyester or nylon blends with a high percentage of spandex to achieve stretch.

Seamless:

Typically blends nylon (polyamide) and elastane (spandex) with advanced knitting for stretch and durability.

Seamless leggings tend to use denser fabric compositions, resulting in a more compact and compressive feel. Meanwhile, Cut & Sew leggings can vary in thickness, depending on the fabric and design requirements.

Branding & Finishing

Cut & Sew:

Logos are added via heat transfer, screen printing, or sublimation. This allows for vibrant all-over prints but can wear out over time.

Seamless:

Logos and designs can be directly knitted into the fabric, offering greater durability and integration.

Which Should You Choose?

Your choice depends on your brand’s goals and target audience.

Go for Cut & Sew if:

You want versatile designs for casual and everyday wear.

You need the ability to mix and match fabrics or create bold, printed designs.

You have lower production volume and prefer smaller MOQs.

Opt for Seamless if:

You’re focused on performance and functionality.

You want leggings with integrated compression zones or minimal seams.

You’re targeting a high-intensity fitness audience.

Conclusion

Both cut-and-sew and seamless leggings have their unique advantages. Whether you prioritize customizability and versatility or comfort and performance, understanding these differences can help you make an informed decision for your brand or wardrobe.

If you’re looking to create high-quality leggings tailored to your brand’s needs, reach out to know more how we can help bring your vision to life.

About FittDesign

FittDesign is a full-service design and production company specializing in the sportswear and activewear industry. We provide comprehensive solutions, including innovative design, detailed technical packs, and high-quality manufacturing. Our expertise supports brands in creating functional and durable sportswear that meets the demands of a competitive market.

Ready to Bring Your Activewear Vision to Life?

Contact us today and let’s get started on your project!