What is Screen Printing?

What is Screen Printing?

Screen printing (also known as silkscreen printing) is a simple way of creating an image/design on a surface (e.g. fabric, garment, paper, etc.) by pressing ink through a stenciled screen. Due to its simplicity, screen printing has been around for a very long time and while most people imagine t-shirts when they think of screen printing, this technique is used in many other industries, including more advanced ones such as conductors and resistors.

How Does Screen Printing Work?

The first step is to create the screens (1 for each color in the artwork), so if your artwork has 3 different colors, then you’ll need 3 different screens. The screen-making process is the trickiest, so it should not be rushed. But once you have your screens, you can print as many items as you want.

To get each colored layer of your artwork onto a screen you need to use a photo-emulsion process that involves using chemicals and UV light. Photo emulsion is a thick liquid substance that hardens when exposed to light, making it difficult to remove from surfaces. This property makes it perfect for creating the stencil for the ink to pass through the screen. You can learn about this process in more detail here:

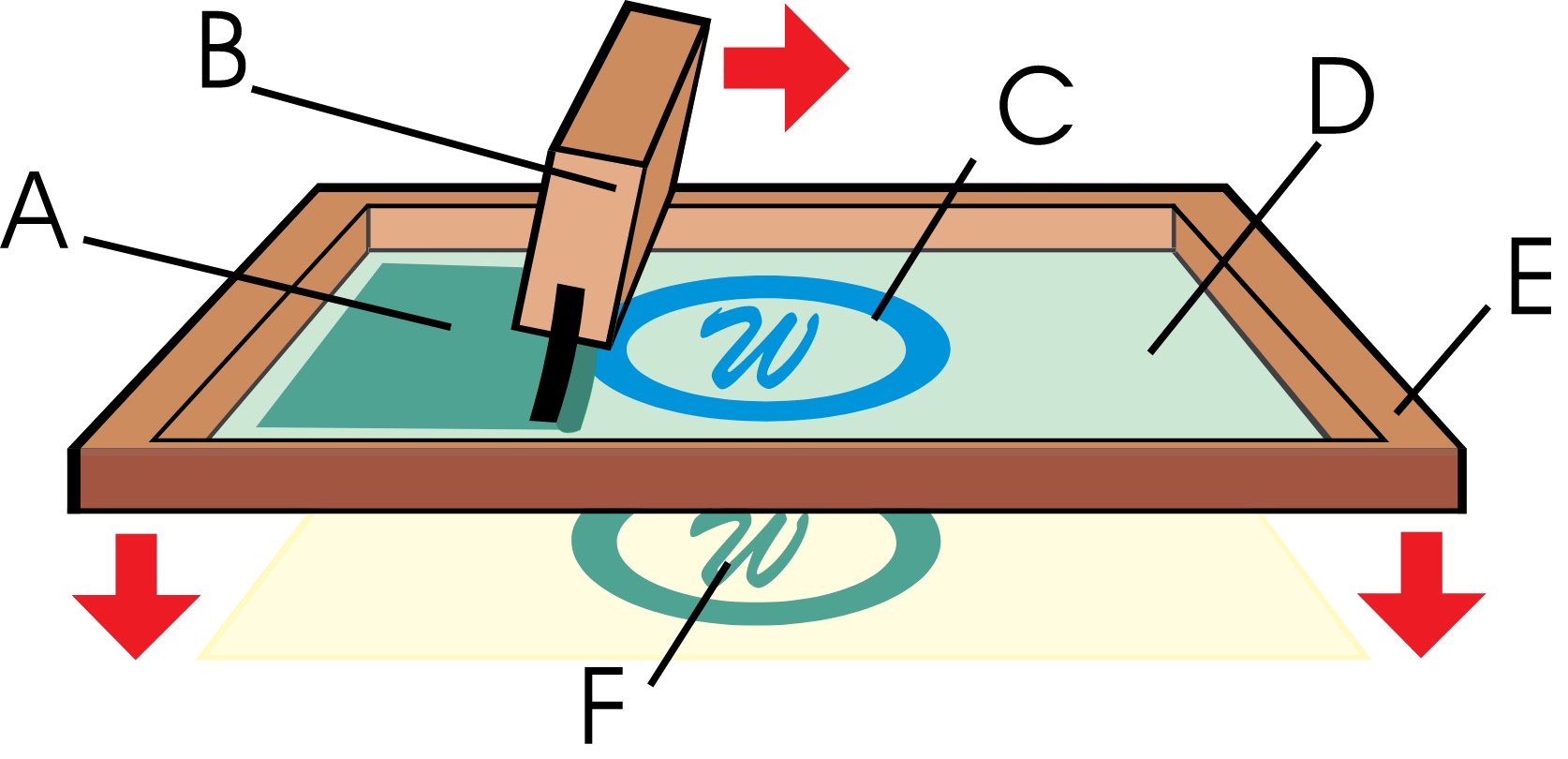

Once you have the screens, you’re ready to ‘print’ them onto the target surface such as a garment. This works by placing the screen above the garment and squeezing the ink through the screen using a squeegee. While this can be done by hand, if you’re printing many pieces, it’s best to use a printing machine. After the ink has been placed, the garment should be heated to seal the ink in.

A. Ink. B. Squeegee. C. Image. D. Photo-emulsion. E. Screen. F. Printed image.

Use screen printing when the artwork consists of just a few colors (no more than 3 to 4), such as logos, phrases, and simple graphics. For anything more complex (photographs, designs with gradations, and complex graphics), we typically go for digital printing. Although it’s technically possible to screen print designs with more than just a few colors, it just becomes a much harder job and the results may not be as good as you want.

WHAT ARE THE BENEFITS OF SCREEN PRINTING FOR APPAREL?

Perfect color reproduction

Long-lasting durability (i.e. resistant to washes)

Cost effective

Simple

WHAT ARE THE MOST COMMON TYPES OF SCREEN PRINTING

Water-based inks – This is a higher-end ink made for super soft shirts (commonly used in retail printing) and usually lasts as long as the garment does.

Plastisol – This is a plastic-based ink and is one of the most common types of ink used in screen printing for apparel, especially for thick prints. Unlike water-based inks, Plastisol ink prints don’t last as long and will easily crack/peel the more you wash and/or dry it.

Discharge – This is also a water-based ink that is mixed with an activator and is used for printing on darker or colored 100% cotton fabrics.

WHAT ARE THE MOST COMMONLY USED MATERIALS TO PRINT ON?

Cotton fabrics

Silk fabrics

Wool fabrics

Acrylic and polyester fabrics

Jersey fabrics

Wood

Ceramics

In conclusion

Screen printing is a timeless and versatile method for transferring designs onto various surfaces, offering perfect color reproduction and durability. Whether it's for apparel, ceramics, or more, this simple yet effective technique continues to leave a lasting impression with its stunning results.

About FittDesign

FittDesign is a full-service design and manufacturing company specializing in the sportswear and activewear industry. We provide comprehensive solutions including innovative design, detailed technical packs, and high-quality manufacturing. Our expertise supports brands in creating functional and durable sportswear that meets the demands of a competitive market.

Ready to Bring Your Activewear Vision to Life?

Contact Us today and let’s get started on your project!