Flat Design Sketches vs. Technical Sketches: Key Differences in Apparel Design

Flat Design Sketches vs. Technical Sketches: Key Differences in Apparel Design

When designing apparel, two key types of sketches are commonly used: flat design sketches and technical sketches. While both are essential tools in fashion design, they serve different purposes and communicate varying levels of detail to designers, manufacturers, and stakeholders. Understanding the differences between them helps ensure your designs are accurately translated from concept to final product.

Flat Design Sketches: A Basic Visual Outline

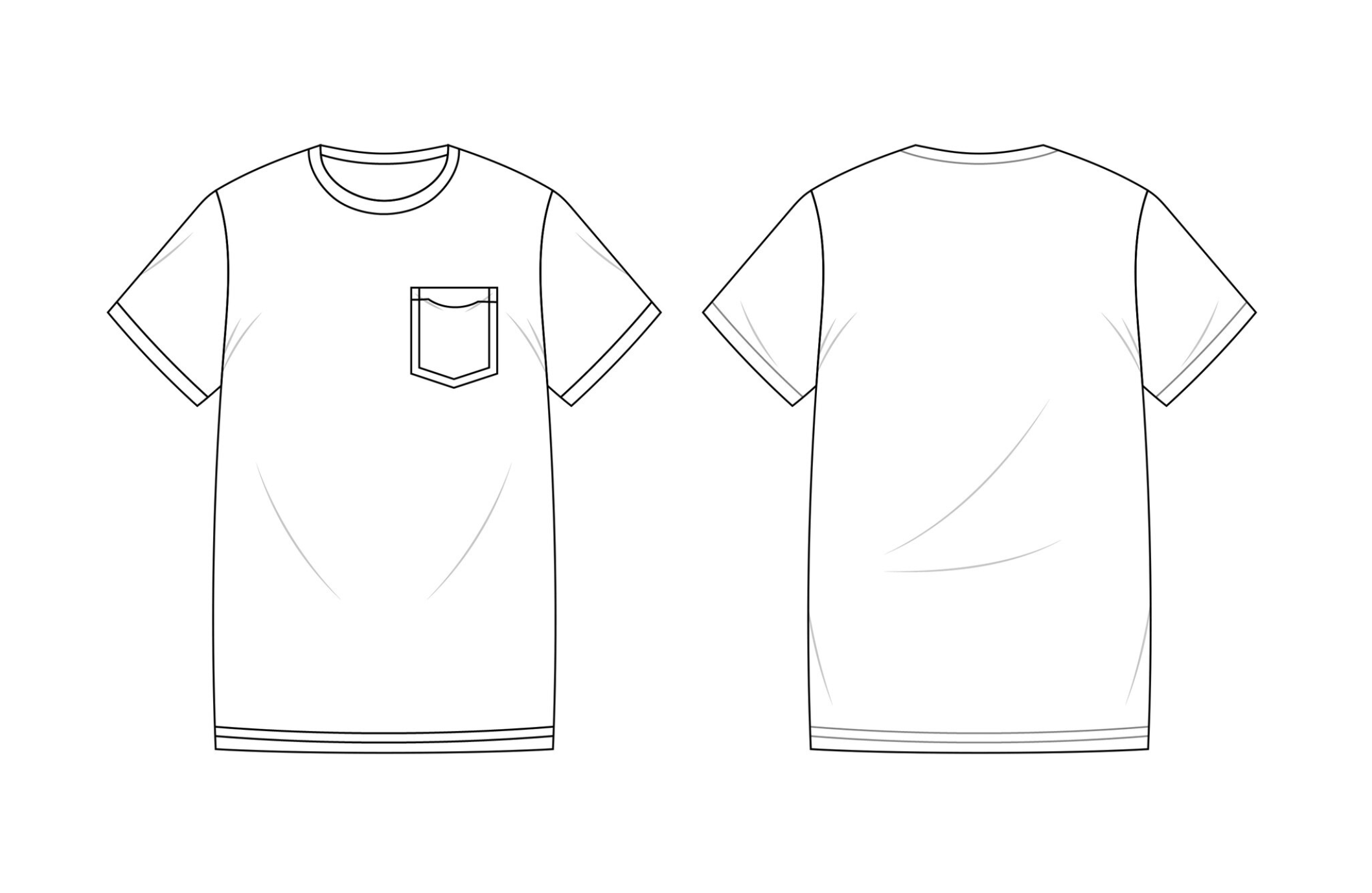

Flat design sketches, also known as flat sketches or fashion flats, are simplified two-dimensional drawings of a garment laid out flat, as if it were placed on a table. These sketches provide a clear, overall view of the garment's basic silhouette and main design features, such as seams, pockets, and closures. Typically, they include front and back views but avoid excessive details on textures, fabric qualities, or stitching techniques.

Flat sketches are primarily used in the early stages of design to communicate the general idea and style of the garment. They help in visualizing how different pieces of clothing fit together and serve as a guide for pattern makers to understand the basic structure. However, flat sketches often lack the in-depth technical details required for production, making them less suitable for manufacturing purposes.

Key features of flat sketches:

Provide a simplified, clean view of the garment.

Include basic design elements like seams, necklines, and pockets.

Used primarily to communicate overall design concepts.

Do not focus on fabric textures or intricate construction details

Technical Sketches: A Detailed Blueprint for Manufacturing

In contrast, technical sketches, often referred to as tech flats, go beyond the basics to include intricate details necessary for the manufacturing process. These sketches are much more detailed and precise, often paired with a tech pack that contains measurements, fabric types, stitching specifications, and trim details.

Technical sketches ensure that manufacturers have all the information they need to accurately construct the garment. They include:

Construction details: Types of seams (e.g., overlock, topstitch), stitch lengths, and placement of zippers or buttons.

Fabric information: Specifying fabric composition, weight, and textures.

Measurement guidelines: Exact dimensions for all components, ensuring proper fit and proportions.

Multiple views: Front, back, side, and even inside-out views to ensure all aspects of the garment are clear to the production team

Unlike flat sketches, technical sketches focus less on the overall style and more on the accuracy of construction. They are critical for communicating precise instructions to factories, especially when working with remote or international production partners.

Key features of technical sketches:

Include detailed construction notes, such as stitching methods and measurements.

Provide full specifications for fabrics, trims, and hardware.

Serve as the primary document for manufacturers to create samples and final products.

Include multiple views and angles for clarity

Conclusion: When to Use Each

While flat design sketches are ideal for brainstorming and conceptual discussions, technical sketches are essential for ensuring that your garment is produced exactly as envisioned. Both types of sketches play critical roles in the apparel design process, but they cater to different stages—flat sketches being useful for initial design discussions, while technical sketches are indispensable during production.

At FittDesign, we specialize in both flat and technical sketches, ensuring your apparel designs move seamlessly from concept to market with precision and creativity. Whether you’re just starting with a design idea or ready to create production-ready tech packs, we’ve got you covered.

About FittDesign

FittDesign is a full-service design and production company specializing in the sportswear and activewear industry. We provide comprehensive solutions, including innovative design, detailed technical packs, and high-quality manufacturing. Our expertise supports brands in creating functional and durable sportswear that meets the demands of a competitive market.

Ready to Bring Your Activewear Vision to Life?

Contact us today and let’s get started on your project!