Knitted vs. Woven Fabrics: A Deep Dive into Textile Nuances

Knitted vs. Woven Fabrics

In the world of fashion and fabrics, there's an ongoing discussion about knitted and woven fabrics. These two fabric types have their unique qualities, and it's essential to know the differences between them. Let's explore what makes knitted and woven fabrics distinct.

The Making of Fabrics

Knitted Fabrics:

Imagine yarn being looped into a continuous, lattice-like structure. Each line of yarn, when looped, forms what we know as knitted fabric. This technique imbues the fabric with its renowned elasticity and stretchiness.

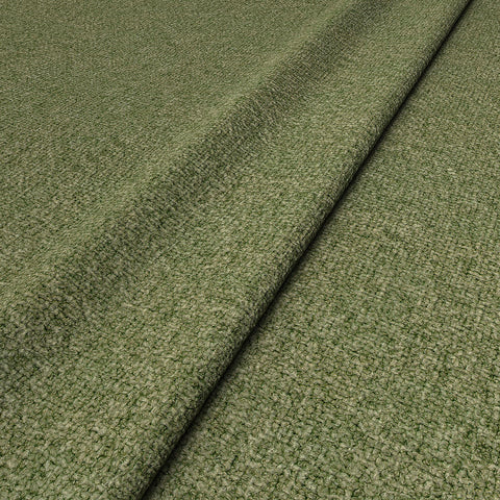

Woven Fabrics:

Here, you'd witness yarns laid out in parallel (known as warp) and then interlaced with perpendicular yarns (called weft). This 90-degree crisscrossing results in a fabric that’s tightly woven and less stretchy. A mnemonic to remember: Weft is left, indicating its horizontal direction.

Physical Properties Examined

Elasticity: Knitted fabrics, due to their looping method, offer superior elasticity. Woven fabrics, though stretchable along the weft, offer little to no stretch along the warp.

Dimensional Stability: Ever noticed a knitted fabric shrink after a wash? They can lose 5-10% of their size, whereas woven fabrics maintain their dimensions and structure, thanks to their tighter weave.

Durability: Woven fabrics stand as champions when it comes to withstand wear and tear. The closely-knit structure of knitted fabrics, however, makes them susceptible to sagging and losing shape over time.

Moisture Absorption: In the battle of moisture-wicking, woven fabrics emerge as victors. Their tight weave repels moisture, making them ideal for sportswear. Knitted fabrics, on the other hand, tend to soak up more moisture.

Slacking: Woven fabrics resist sagging and maintain structural integrity far longer than knitted fabrics.

Air Permeability: Think of windbreakers – they often employ woven fabrics. The tight weave ensures minimal air permeability, providing excellent insulation. Conversely, the porous nature of knitted fabrics makes them less effective as wind barriers.

Creasing: A woven shirt may often demand an iron, while a knitted top remains relatively wrinkle-free. The nature of woven fabrics means they crease more easily.

Production & Cost Insights

Woven fabric production typically involves more advanced machinery and setup, often relying on looms (both manual and machine-operated). This intricacy results in higher upfront costs. Additionally, the denser weave of woven fabrics means more yarn per square meter, increasing both production costs and overall material consumption. Knitted fabrics, being simpler in production, generally come with more modest manufacturing demands.

In Conclusion

Each fabric type, knitted or woven, serves its unique purpose in the vast world of textiles. Their individual attributes make them suited for specific applications, whether it's the cozy stretch of a knitted sweater or the structured elegance of a woven blazer. The next time you pick an outfit or plan a purchase, you'll appreciate the craftsmanship and science behind each thread.

About FittDesign

FittDesign is a full-service design and production company specializing in the sportswear and activewear industry. We provide comprehensive solutions including innovative design, detailed technical packs, and high-quality manufacturing. Our expertise supports brands in creating functional and durable sportswear that meets the demands of a competitive market.

Ready to Bring Your Activewear Vision to Life?

Contact Us today and let’s get started on your project!